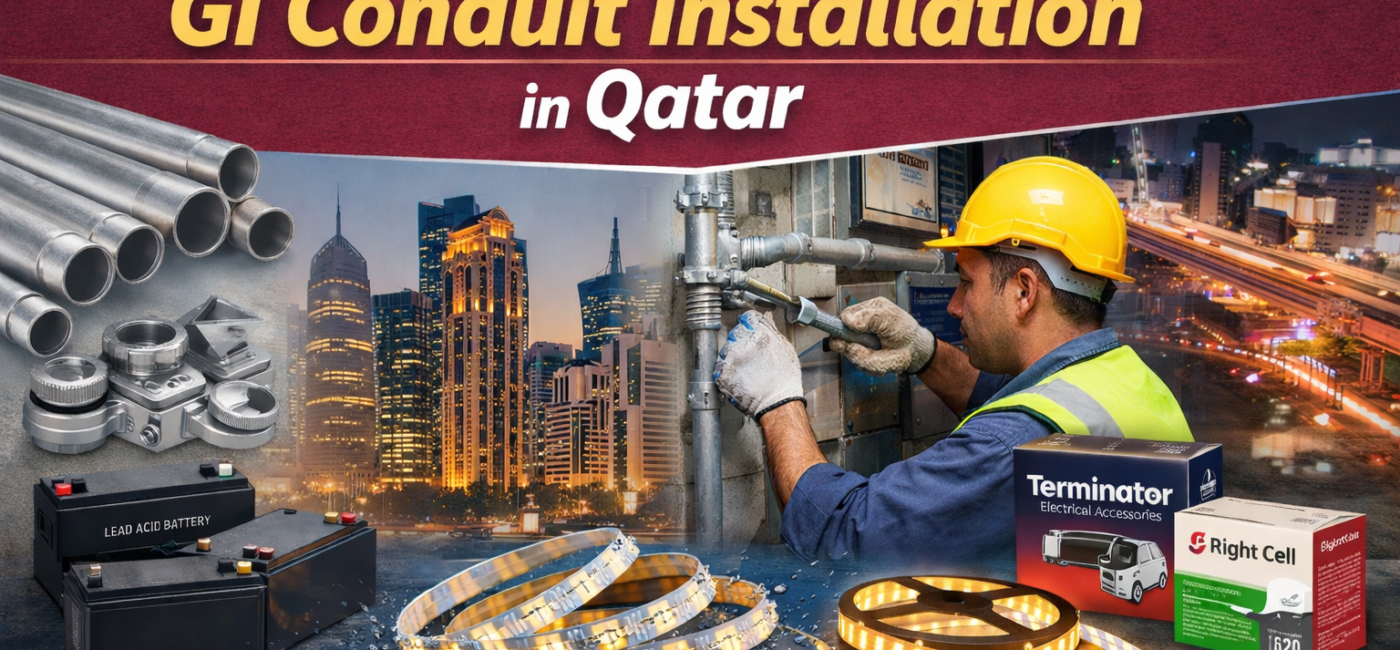

Qatar’s rapid urban development, driven by large-scale infrastructure, commercial, and industrial projects, places a strong emphasis on electrical safety, reliability, and long-term performance. Among the most essential components of any electrical system are GI (Galvanized Iron) conduits, which serve as a protective pathway for electrical wiring. This blog provides an in-depth overview of the standards for GI conduit installation in Qatar, with a special focus on EMT, GI conduits & accessories in Qatar, along with related power and lighting solutions widely used in the country.

The Role of EMT & GI Conduits in Qatar’s Construction Environment

Qatar’s environment presents unique challenges such as extreme heat, coastal humidity, sand, and airborne dust. These conditions can significantly affect electrical systems if not properly protected. This is why EMT, GI conduits & accessories in Qatar are extensively specified in residential towers, commercial complexes, oil & gas facilities, and infrastructure projects.

GI conduits offer:

- High mechanical strength to protect cables from impact and vibration

- Excellent resistance to corrosion when properly galvanized

- Fire resistance compared to non-metallic alternatives

- Enhanced grounding capability for electrical safety

These features make GI conduits a preferred choice for consultants and authorities approving electrical installations in Qatar.

Applicable Standards and Regulatory Requirements in Qatar

Electrical conduit installation in Qatar must strictly comply with Qatar Construction Specifications (QCS) and Kahramaa Electrical Regulations, supported by international standards such as IEC and British Standards (BS). These standards govern the material quality, installation method, and testing requirements for EMT, GI conduits & accessories in Qatar.

Key regulatory requirements include:

- Use of approved EMT and GI conduits with uniform galvanization

- Proper bonding and earthing of all metallic conduit systems

- Installation of conduits with approved saddles and clamps at defined intervals

- Use of certified fittings, couplers, elbows, and junction boxes

Non-compliance can lead to rejection during inspection, project delays, or future operational risks.

Detailed GI Conduit Installation Practices

Proper installation plays a crucial role in ensuring system safety and durability. In Qatar, the standard practice for installing EMT, GI conduits & accessories includes careful planning and execution.

Conduit Routing and Layout

Conduits must be routed to minimize sharp bends and excessive lengths. The number of bends between pull points is limited to reduce cable stress. Approved bending tools are used to maintain the minimum bending radius as per standards.

Fixing and Support

GI conduits are securely fixed using corrosion-resistant saddles and brackets. The spacing between supports must comply with local standards to prevent sagging or vibration, especially in industrial environments.

Jointing and Termination

All conduit joints must be tightly secured using threaded or compression-type fittings. Accessories such as Terminator products are commonly used for safe and reliable cable termination, ensuring electrical continuity and mechanical stability.

Integration with Power Backup Systems

In many commercial and industrial facilities, Lead acid batteries are used for UPS systems, emergency lighting, telecom infrastructure, and backup power solutions. GI conduit systems provide essential protection for battery cables, preventing mechanical damage, heat exposure, and accidental contact.

Well-installed EMT, GI conduits & accessories in Qatar ensure that power from Lead acid batteries is distributed safely and efficiently, particularly in mission-critical applications such as hospitals, data centers, and transportation facilities.

Compatibility with High-Quality Electrical Components

Qatar’s electrical projects often specify premium electrical brands to ensure performance and longevity. Products from Bright Cell are widely used for energy storage and electrical reliability, while Terminator accessories support secure connections within GI conduit systems.

The compatibility of EMT, GI conduits & accessories in Qatar with these trusted brands enhances system integrity and reduces the risk of electrical faults.

GI Conduits in Modern Lighting Installations

Architectural and commercial projects increasingly use advanced lighting solutions, including IP20 & IP67 LED strip lights. IP20 LED strip lights are commonly used in indoor applications such as offices, malls, and residences, while IP67 LED strip lights are designed for outdoor and moisture-prone environments.

GI conduits protect the wiring supplying these lighting systems, especially in exposed areas. Brands such as AKTO provide LED lighting solutions that integrate seamlessly with standardized conduit installations, ensuring safety, aesthetics, and long-term performance.

Testing, Inspection, and Quality Assurance

Before commissioning, all GI conduit installations in Qatar must undergo thorough inspection and testing. Authorities verify:

- Continuity of earthing and bonding

- Secure fixing and correct spacing

- Smooth internal surfaces to avoid cable damage

- Compliance with approved drawings and specifications

Using certified EMT, GI conduits & accessories in Qatar significantly improves approval rates and ensures a smooth handover process.

Long-Term Benefits of Standardized GI Conduit Systems

Adhering to approved standards for GI conduit installation offers multiple long-term advantages:

- Improved electrical safety and fire protection

- Reduced maintenance and downtime

- Extended lifespan of cables and accessories

- Better compatibility with future system upgrades

These benefits make GI conduit systems a long-term investment rather than just a regulatory requirement.

Conclusion

The standards for GI conduit installation in Qatar reflect the country’s commitment to safety, quality, and sustainable infrastructure development.

By following approved standards and best practices, contractors and developers can ensure durable, compliant, and future-ready electrical systems across all types of projects in Qatar.